Forklifts are the unsung heroes of modern industry, responsible for moving massive loads and streamlining material handling in warehouses worldwide. Yet, few people know the fascinating history behind these indispensable workhorses. Join us as we explore the evolution of the forklift, from humble beginnings to the advanced machines we know today – a journey we like to call “forklift history: the journey of industry’s workhorse.”

Key Takeaways

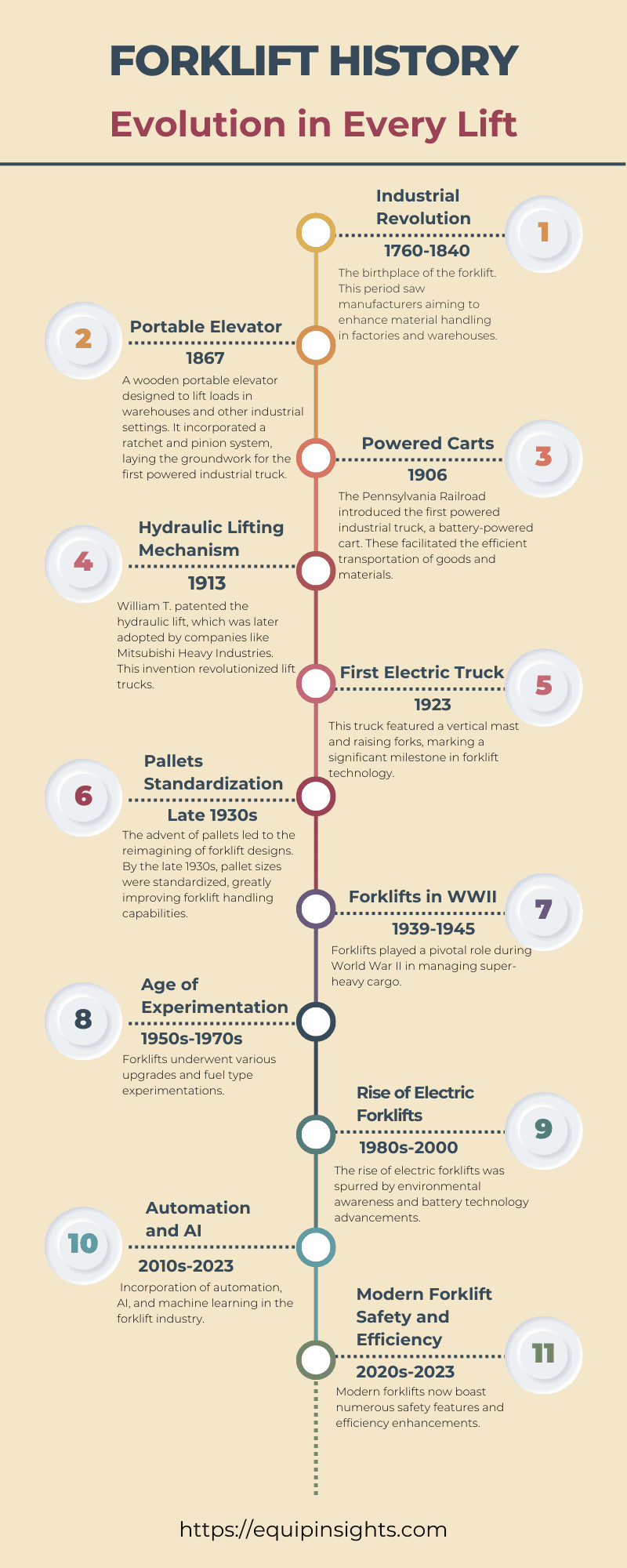

- The forklift was born in the Industrial Revolution, revolutionizing material handling and providing safety for operators.

- The introduction of battery-powered carts and William T.’s hydraulic lifting mechanism Advanced lift trucks & forklifts, enabling efficient material handling up to 90 tons.

- Standardized pallet sizes have enabled improved warehousing processes, with modern advancements such as automation/AI offering immense potential for increased efficiency and safety.

The Birth of the Forklift: Early Innovations

The forklift’s origins trace back to the Industrial Revolution, a period when manufacturers aimed to enhance material handling in factories and warehouses. Early innovations included wrought-iron axles and cast iron wheels, portable elevators, and powered carts, which paved the way for the hydraulic lifting mechanisms that revolutionized the industry.

The first electric truck, introduced in 1923, featured a vertical mast and raising forks, marking a significant milestone in forklift technology. These initial forklifts significantly reduced manual labor and efficiently managed diverse loads in warehouses, becoming indispensable in materials handling. To ensure the forklift operators safety, overhead guards and load backrests were provided.

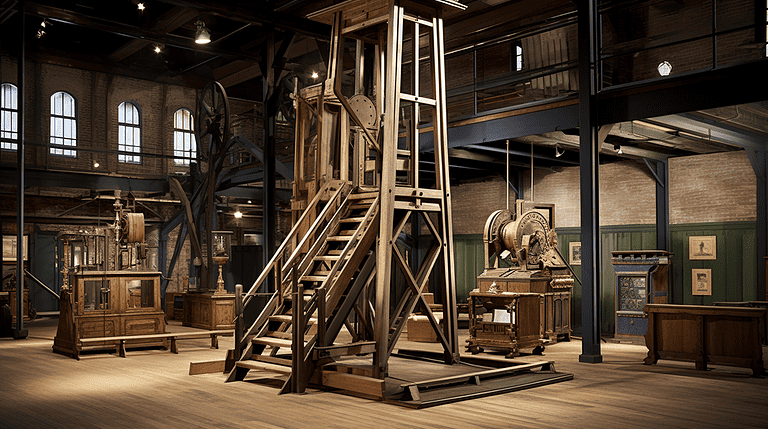

Portable Elevator

In 1867, a portable elevator made from wood was designed to lift loads in warehouses and other industrial settings. This early load-bearing machine sought to improve on its predecessor by incorporating a ratchet and pinion system, laying the groundwork for the first powered industrial truck.

Serving as the forerunners of today’s forklifts, portable elevators significantly influenced the evolution of the material handling equipment industry. Their innovative design allowed for the convenient relocation and installation in various locations, making them an essential piece of equipment in factories and warehouses.

Powered Carts

The first powered industrial truck, a battery-powered cart, was introduced by the Pennsylvania Railroad in 1906. These powered carts, also known as powered trucks, facilitated the convenient and efficient transportation of goods and materials, promoting the usage of lift trucks in various industries.

The introduction of battery-powered platform trucks established the groundwork for the modern forklift, enabling improved efficiency and flexibility in material handling tasks. This development marked a turning point in the history of the forklift and set the stage for further innovation in the field.

Hydraulic Lifting Mechanism

William T. was the pioneer of the hydraulic lift, having patented it himself. This was an innovative development in engineering at the time. Harris in 1913 and later adopted by companies like Mitsubishi Heavy Industries, revolutionized lift trucks.

This groundbreaking invention allowed for more efficient material handling and boosted the capacity of forklifts, paving the way for the modern forklift driver in warehouses and other industrial settings.

The lift tractor, the predecessor of the modern forklift, was developed in the 1920s, further transforming the material handling landscape. With the ability to lift loads of up to 90 tons, the hydraulic lifting mechanism demonstrated the immense potential of forklift technology to shape the industry.

The Standardization of Pallets and Its Impact on Forklift Design

The advent of pallets called for a reimagining of forklift designs, consequently simplifying the warehouse storage process. Early pallet variations, such as reversible and non-reversible pallets, as well as winged pallets, posed challenges for forklift operators due to the lack of standardized sizes.

By the late 1930s, pallet sizes were standardized, greatly improving forklift handling capabilities. The adoption of standard pallet sizes allowed forklifts to be designed to fit a single size of pallet, facilitating the production of more dedicated forklifts and the introduction of automated systems that could quickly and accurately transfer pallets from one area to another.

Early Pallet Variations

The absence of standardized pallet sizes in the early days of the forklift industry presented numerous challenges for operators. The variety of pallet types, including reversible, non-reversible, and winged pallets, made loading, unloading, and maneuvering pallets a difficult task.

Forklift operators struggled with these early pallet variations, which often led to inefficiencies in material handling processes. The lack of standardization impeded the smooth operation of warehouses and factories, highlighting the need for a more uniform approach to pallet design.

The Adoption of Standard Pallet Sizes

The standardization of pallet sizes revolutionized the forklift industry, enabling more effective material handling and the development of specialized forklifts and automated systems. The prevalence of standard pallet sizes, such as the 48×40 pallet, has become an international standard by default, with various countries and regions adopting their own standard sizes.

The adoption of standard pallet sizes has led to numerous benefits for the material handling industry. Some of these benefits include:

- Forklifts designed to accommodate specific pallet sizes, allowing warehouse managers to strategize their fleets and procure new and pre-owned forklifts more effectively.

- Faster and more efficient material handling due to the standardization of pallet sizes.

- Improved safety for workers.

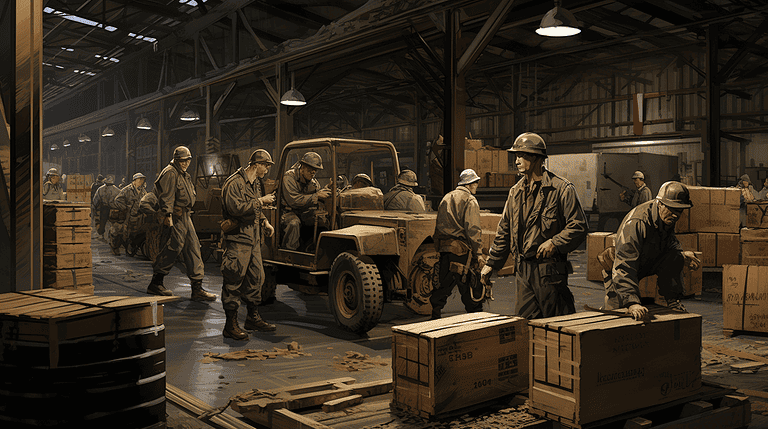

Forklifts During World War II

During World War II, forklifts played a pivotal role in managing super-heavy cargo and increasing the efficiency of warehouse and factory operations with fewer personnel. Companies like Clark Material Handling Company, Yale, and Hyser provided the majority of forklifts used by the U.S. military economy, making a significant contribution to the war effort.

Forklift trucks proved invaluable for loading, organizing, and transporting materials and equipment, demonstrating their effectiveness under high-pressure wartime environments. Their widespread usage during this period solidified the forklift’s status as an indispensable tool in material handling and showcased their potential for further innovation in the years to come.

The Age of Experimentation and Advancements

During the Age of Experimentation and Advancements, forklifts underwent various upgrades, like the shortening of wheelbases, introduction of new operator compartments, and the addition of tilting features. Experimentation with different fuel types, such as gasoline, diesel, and electric, also took place during this period, further expanding the possibilities for forklift technology.

This era of remarkable innovation and progression resulted in numerous improvements to forklifts and the exploration of various fuel types. The advancements made during this time laid the foundation for the modern forklift industry and paved the way for future breakthroughs in material handling technology.

The Rise of Electric Forklifts

The rise of electric forklifts has been spurred on by growing environmental awareness, the need for sustainable and efficient material handling solutions, and advancements in lithium battery technology. These eco-friendly lift trucks offer cost savings in terms of fuel costs, reduced carbon dioxide emissions, and increased operational efficiency.

The global electric forklift market is anticipated to reach billions by 2028, with a CAGR of over 6%. Electric lift trucks provide environmental benefits and boast a load handling capacity of over 15,000 pounds, demonstrating their potential to reshape the material handling landscape.

Automation and AI in the Forklift Industry

The incorporation of automation, AI, and machine learning in the forklift industry is paving the way for enhanced efficiency, safety, and less dependence on human labor. While automation has proven beneficial for tasks that are repetitive in nature, it has not yet advanced to the point of being able to handle more complex workflows and high-level decision-making.

The implementation of 5G technology in the forklift industry can:

- Improve connectivity

- Optimize corporate operations and production activities

- Permit warehouse managers to plan activities such as predictive maintenance and repairs with immediate feedback from AI forklifts on the 5G network.

The potential implications of automation and AI in the forklift industry are vast, opening up new possibilities for increased efficiency and safety in material handling operations.

Fuel Innovations: Lithium-Ion Batteries and Fuel Cells

Lithium-ion batteries, due to their faster charging time, enhance forklift efficiency by facilitating longer shifts. In addition to their efficiency, lithium-ion batteries also provide a more environmentally friendly alternative to traditional lead-acid batteries.

Fuel cell technology, which generates electricity through a chemical reaction between hydrogen and oxygen, is another innovation in the forklift industry that has the potential to transform material handling processes. Fuel cell technology is anticipated to offer multiple choices for managers when strategizing their fleets and procuring new and pre-owned forklifts, further expanding the range of possibilities in the forklift industry.

The Modern Forklift: Safety and Efficiency Improvements

Modern forklifts, having evolved significantly from their initial versions, now boast numerous safety features and efficiency enhancements. The Active Mast Function Control System is an important safety feature that protects the operator by limiting the forward and rear tilt speed when instability is detected. This helps to prevent costly tip-overs. Additionally, the SAS system stabilizes the rear axle when instability is detected, further aiding in keeping the truck upright.

Predictive maintenance, a method of servicing equipment in advance to anticipate and avoid breakdowns based on usage data, has also emerged in the modern forklift industry. This can provide several benefits, including:

- Alerting drivers to potential issues before they become more serious

- Increasing productivity

- Increasing driver safety

- Creating remote work opportunities.

The advancements in forklift technology continue to shape the materials handling equipment industry, ensuring that forklifts remain an essential tool in warehouses and factories worldwide.

The Future of the Forklift Industry

The forklift industry continually evolves, with forklift manufacturers introducing new technologies to bolster safety, efficiency, and productivity for forklift drivers.

As the industry continues to grow and adapt to the ever-changing demands of material handling processes, we can only speculate on the potential developments and innovations that lie ahead.

I’m really curious to know what the future holds for the forklift industry? Do you have any ideas on this? Will we see even more advanced safety features, further automation, or perhaps entirely new fuel sources?

Conclusion

From their early beginnings as portable elevators and powered carts to the advanced machines we know today, forklifts have played a crucial role in shaping the material handling industry. With ongoing advancements in safety, efficiency, and technology, the forklift continues to evolve and adapt to meet the ever-changing demands of warehouses and factories worldwide. As we look to the future, it’s clear that the forklift industry will continue to innovate and push the boundaries of what is possible, ensuring that these indispensable workhorses remain at the forefront of material handling.

Frequently Asked Questions

What's the origin of the forklift?

Forklifts originated in the Industrial Revolution with innovations like portable elevators and powered carts. The first electric version appeared in 1923.

Why are forklifts crucial in warehouses?

Forklifts efficiently move massive loads, streamlining material handling in warehouses globally.

How did World War II impact the use of forklifts?

During WWII, forklifts were essential for handling super-heavy cargo, enhancing warehouse and factory operations.

What innovations led to the modern forklift?

Innovations include portable elevators (1867), battery-powered carts (1906), and William T.'s hydraulic lift (1913).

How are pallet sizes significant in forklift design?

Standardized pallet sizes by the late 1930s improved forklift handling and led to specialized designs.

What's the future of electric forklifts?

Electric forklifts are gaining traction due to environmental concerns and advancements in battery tech, with a significant market growth expected by 2028.

How is AI impacting the forklift industry?

AI and automation promise enhanced efficiency, safety, and reduced human labor dependency in the forklift industry.

What are the benefits of modern forklifts?

Modern forklifts offer safety features and efficiency enhancements, like the Active Mast Function Control System and predictive maintenance.

References

https://www.grandviewresearch.com/industry-analysis/forklift-market

https://education.nationalgeographic.org/resource/industrial-revolution-and-technology/

https://www.lillyforklifts.com/blog/the-history-of-the-forklift

https://www.lowtechmagazine.com/2010/03/history-of-human-powered-cranes.html

https://en.wikipedia.org/wiki/Pennsylvania_Railroad

https://www.thomasnet.com/articles/materials-handling/understanding-pneumatic-and-hydraulic-lifts/

https://www.tehrantimes.com/news/484291/The-history-of-pallets-and-their-applications-up-to-now

https://en.wikipedia.org/wiki/American-logistics-in-the-Normandy-campaign

https://www.un.org/sustainabledevelopment/sustainable-consumption-production/

https://www.simplilearn.com/growing-role-of-ai-in-manufacturing-industry-article

https://www.globenewswire.com/en/news-release/2023/08/14/2724634/0/en/New-Market-Study-Global-Electric-Forklift-Market-is-expected-to-reach-US-7-1-billion-by-2028-registering-a-CAGR-of-over-6.html