As the e-commerce sector races ahead, the logistics industry is grappling with the need for rapid order fulfillment. Amidst this, Automation in Warehousing emerges as a pivotal game-changer, promising efficiency, cost-effectiveness, and the capacity to meet increasing customer demands.

However, the adoption of automated systems in the warehousing industry, despite its vast potential, is hindered by several roadblocks.

This article unpacks the current trends in warehouse automation, delving deep into automated storage and retrieval systems, and the dynamics of inventory management.

We will explore the barriers to the integration of automation systems and present strategies to overcome these challenges, positioning automation as a business imperative in the warehousing and logistics industry.

Key Takeaways

- Half of warehousing leaders plan to adopt automation technology in the next five years.

- Challenges include integration difficulties, resistance, and lack of automation expertise.

- Many leaders are hesitant about fully autonomous vehicles but are leaning towards semi-automated systems.

- Mobile robots and autonomous mobile robots are emerging as innovative solutions.

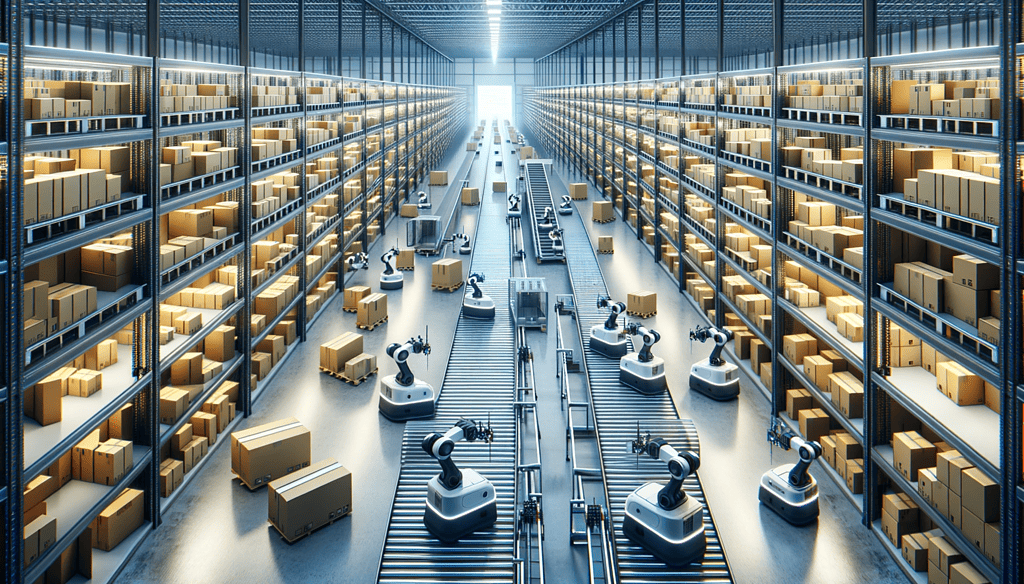

Automation Adoption in Warehousing

The adoption of automation in warehousing operations, particularly automated storage and retrieval systems, is undeniably on the rise. A recent study by the Warehousing Education and Research Council (WERC) reveals that the adoption of warehouse automation has increased by approximately 27% over the past three years.

Yet, even with this growth, various research indicates that only a fraction of industry leaders have fully embraced this transformative technology. A detailed analysis of the warehouse automation market projects a growth rate of 11% annually, expected to reach a market valuation of over $25 billion by 2025.

This increasing trend towards automation, however, is not without its challenges. Many industry leaders are hesitant, mainly due to integration difficulties, internal resistance, and a notable lack of automation expertise.

The Warehousing and Logistics Barometer report highlights that about 33% of surveyed warehouse managers believe they lack the necessary skill set to implement and manage automation technologies effectively.

However, in examining the latest warehouse automation trends, it becomes evident that advances in warehouse technology, such as robotics, artificial intelligence, and machine learning, are revolutionizing the sector.

These technologies not only simplify the implementation process but also offer a higher return on investment. For instance, automated mobile robots have been found to increase warehouse efficiency by up to 40%, reducing manual labor needs and operational costs.

With industry reports suggesting that labor costs can account for over 50% of a warehouse’s operational budget, the shift towards automated systems can result in significant cost savings.

Furthermore, automation technologies are bridging the skill gap by offering intuitive systems that require minimal training, making it easier for warehouses to adopt and adapt to these changes. This transition, backed by factual evidence and market research, facilitates a secure automated network integration, signaling a promising future for the warehousing sector.

Amazon's Robotics Revolution: The Proteus Initiative

Amazon, a global e-commerce titan, is a prime example of a company pushing the boundaries of warehouse automation. Their innovative robot, Proteus, operates alongside human employees, navigating the warehouse floor as humans do. Enhanced with computer vision and artificial intelligence, robots like the Cardinal sort items rapidly, preparing them for dispatch.

This seamless integration of robots into Amazon’s warehousing operations underlines the potential of automating tasks traditionally done by humans. It’s not just about speeding up processes but about enhancing accuracy and efficiency.

Barriers to Implementing Automation in Warehousing

The path to full-scale automation in warehousing, while promising, is laden with challenges. Several barriers stand in the way of industry leaders eager to embrace the future.

Lack of Expertise

The world of warehouse automation technologies is evolving rapidly. While 28.3% of leaders in the logistics industry identify a lack of automation expertise as a major impediment, others feel the pressure of keeping up with the ever-changing landscape. As automation technologies become more intricate, the learning curve becomes steeper, emphasizing the importance of continuous education and training.

Integration Challenges

For warehouse operators, the dilemma isn’t just about adopting new technologies; it’s about making them work with existing systems. Nearly a quarter of them grapple with how to seamlessly weave in automation technologies into their current operations, especially when dealing with legacy systems and the emerging cloud-based warehouse management platforms.

The Human Factor – Internal Resistance

Change is hard, and the human element cannot be overlooked. The apprehension isn’t just about new tools; it’s about shifting paradigms. Around 22% of industry leaders note that their teams resist the adoption of automation technologies. This resistance often stems from concerns about job roles, workplace culture, and the fear of the unknown.

Support and Maintenance Concerns

As with any technology, automation technologies come with their set of maintenance challenges. Ensuring systems are up-to-date, especially in areas driven by artificial intelligence and machine learning, is a concern. For 22% of warehouse operators, the perceived complexities of maintaining these systems loom large, making them hesitant to fully commit.

These barriers underscore the complexities of the automation journey in warehousing. Addressing each concern holistically is vital for the industry to move forward and fully harness the potential of automation.

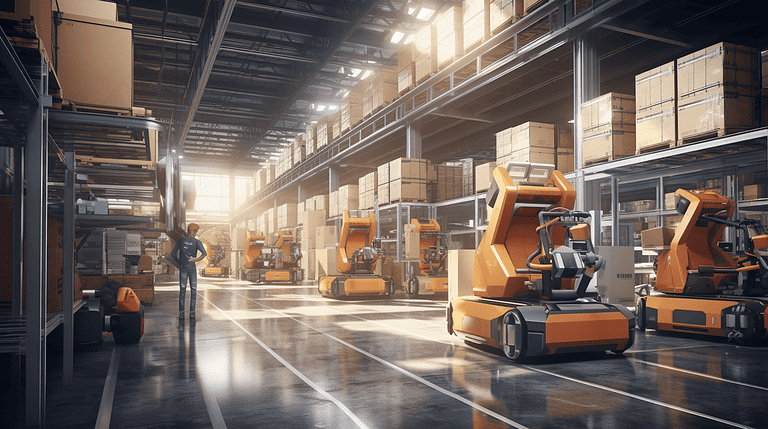

Embracing Collaborative Automation

The landscape of warehousing is undergoing a significant transformation, thanks to a harmonious collaboration between humans and robots. This innovative approach, aptly termed ‘CollaboMation’, is a testament to the potential of human-machine synergy. Central to this evolution are cobots.

Distinct from traditional automation robots, cobots are designed to work seamlessly alongside humans. A report from the Material Handling Institute (MHI) suggests that warehouses utilizing cobots have seen a 28% increase in productivity, with a 20% reduction in injury rates.

These cobots, adept at navigating the warehouse floor, can efficiently handle tasks like lifting heavy items, ensuring faster turnaround times. Meanwhile, human workers can channel their expertise towards tasks demanding precision, critical thinking, and a human touch.

This approach isn’t about overhauling existing warehouse operations but augmenting them. A study by the Warehousing and Fulfillment Process Benchmark & Best Practices Guide highlighted that implementing cobots resulted in a 15% reduction in operational costs for many warehouses. Their in-built sensors and adaptive programming make them inherently safe, minimizing the risk of accidents.

Beyond just efficiency, this collaboration has another edge: adaptability. While cobots excel at repetitive tasks, humans tackle challenges requiring adaptability and nuanced decision-making. The blend ensures a dynamic and responsive warehouse environment.

To sum it up, collaborative automation is more than a trend. Backed by tangible results and industry studies, ‘CollaboMation’ is setting the stage for a future where warehousing is not only more efficient but also more adaptive and resilient.

Driving Forces of Warehouse Automation

The momentum behind warehouse automation is not spontaneous. It’s propelled by a confluence of global factors, each amplifying the need for more sophisticated and efficient warehousing solutions.

E-commerce Surge

The boom in online shopping has put pressure on businesses to deliver faster and more accurately than ever before. As customer demand grows, the need for efficient warehouse operations becomes paramount. The Precedence Research highlighted that the sector saw a growth of over 30% in the past year, emphasizing the urgency for robust warehouse automation systems.

Rising Labor Costs

Across the globe, labor costs are on an upward trajectory. The Global Wage Report indicates that wages have increased by approximately 5% annually in major economies. This rise nudges companies to explore ways to optimize operations and reduce labor costs. Automation, especially with mobile robots and automated storage and retrieval systems, offers a viable solution.

Technological Maturation

The world of warehouse technology is not what it used to be. Innovations in artificial intelligence, machine learning, and robotics are no longer experimental; they’re proven. Their reliability and efficiency have been validated in numerous industries, making their integration into warehousing a logical step forward.

Complex Supply Chains

In today’s interconnected world, supply chains are more intricate than ever. Real-time visibility and rapid response times have become necessities. The Global Supply Chain Report emphasized the increasing importance of warehouse management systems and automation technologies in ensuring seamless operations amidst these complexities.

In essence, these driving forces are not mere trends; they represent a paradigm shift in the way the warehousing and logistics sectors operate. With each factor reinforcing the other, the move towards comprehensive automation seems not only beneficial but inevitable.

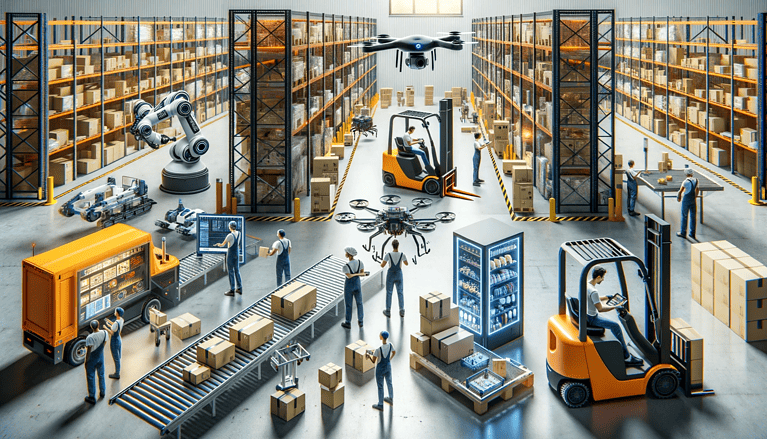

Emerging Trends in Warehouse Automation

The realm of warehousing is always in flux, with new technologies and strategies continually reshaping the landscape. As we look to the future, several emerging trends stand out, promising to redefine how logistics companies operate:

Cloud-Based Warehouse Management

The shift to the cloud is undeniable. More companies are moving away from traditional on-premises systems in favor of cloud-based warehouse management systems. This migration not only reduces infrastructure costs but also offers unparalleled scalability. A recent study by the Logistics Management Institute found that companies adopting cloud-based solutions reported a 20% improvement in inventory accuracy.

Mobile Robot Revolution

Gone are the days of static conveyors. Today’s mobile robots are agile, adaptable, and efficient. They can swiftly navigate complex warehouse layouts, adapting in real-time to obstacles and changing demands. Their utility has led to an estimated 40% reduction in warehouse floor traffic, as noted by the Automated Mobile Robotics Report.

Big Data & Analytics

Data is the new gold, especially in warehousing. Harnessing vast amounts of warehouse data allows companies to optimize operations, streamline inventory management, and predict future trends. Advanced analytics tools are enabling companies to make data-driven decisions, leading to enhanced warehouse efficiency.

Machine Learning in Labor Planning

Machine learning isn’t just a buzzword. It’s making tangible differences in how warehouses manage their workforce. By analyzing patterns, predicting peak times, and understanding workflow dynamics, machine learning tools are helping optimize labor allocation.

Robots-as-a-Service (RaaS)

Investing in automation doesn’t necessarily mean buying robots. The RaaS model allows companies to lease robots, providing flexibility to upscale or downscale based on demand. This approach, gaining traction in the industry, ensures that companies can access cutting-edge technology without the upfront capital costs.

Warehouse Drones

Aerial drones are making their mark in warehousing. From scanning inventory in high shelves to assisting in inventory management, drones offer a unique perspective, literally and figuratively. Their adoption is set to revolutionize how warehouses track inventory and manage space.

These trends are not mere flashes in the pan. They are indicative of a larger shift towards a technologically-integrated, data-driven, and highly efficient warehousing ecosystem. As these trends gain momentum, the warehousing industry is poised to witness transformative changes in the coming years.

Walmart's Automated Warehousing: A Retail Giant's Strategy

The retail behemoth, Walmart, showcases the potential of automated storage and retrieval systems. Recognizing the intricacies of managing vast inventories, Walmart acquired Alert Innovations, a robotic automation company.

The objective? To implement cutting-edge automated storage and retrieval technology in their vast network of fulfillment centers. Such strategic moves by giants like Walmart underscore the significance of automation in streamlining inventory management and optimizing warehouse operations.

Future Predictions: The Horizon of Warehouse Automation

As the world stands on the precipice of a fourth industrial revolution, warehouse automation is poised to play a pivotal role in this transformation. Here are some predictions for the future of warehouse automation:

- Rise of Smart Warehouses:

With the fusion of the Internet of Things (IoT) and automation technologies, warehouses will transform into intelligent hubs. These smart warehouses will employ sensors and advanced analytics to optimize storage, track inventory in real-time, and predict maintenance needs.

- Integration of Augmented Reality (AR):

AR will revolutionize picking and sorting processes. Workers equipped with AR glasses could receive real-time data about inventory locations, optimal pick paths, and even product details, streamlining operations and reducing errors.

- Sustainability Focus:

As businesses globally emphasize sustainability, automated warehouses will prioritize energy efficiency and waste reduction. This could involve solar-powered robots, smart lighting systems, and recycling initiatives integrated into the automation process.

- Advanced Human-Robot Collaboration:

Beyond cobots, the future will see more nuanced collaboration between humans and machines. This might involve robots understanding human gestures or voice commands, creating a seamless working environment.

- Decentralization of Warehouses:

With drone deliveries becoming a reality, we might see a rise in micro-warehouses in urban areas. These smaller hubs will rely heavily on automation to efficiently operate in compact spaces and ensure speedy deliveries in cities.

- Adaptive Automation:

Leveraging artificial intelligence, automation systems in the future will be capable of self-optimization. They will learn from daily operations, adapt to changes in demand or inventory, and even reconfigure layouts or processes autonomously.

Frequently Asked Questions

How Can Smaller Businesses Effectively Adopt Warehouse Automation?

Begin with budget-friendly options like autonomous mobile robots and cloud-based management systems. They're scalable with minimal setup changes, fitting budget constraints.

What Strategies Overcome Internal Resistance to Automation in Warehousing and Logistics?

Education is crucial. Share the benefits like enhanced safety and efficiency with staff. Engage them in decision-making for a smoother transition and reduced resistance.

How Can Businesses Measure Warehouse Automation Project Success?

Measure success using key performance indicators like order accuracy, throughput rate, and operational costs. Evaluating return on investment also gives a clear project impact insight.

Which Industries Benefit Most from Automation in Warehousing and Logistics?

Definitely. Sectors like e-commerce, retail, and manufacturing with high-volume, repetitive tasks benefit greatly from automation, enhancing efficiency and managing peak demand well.

What Are the Risks in Adopting Automation in Warehouses and Logistics Operations?

Initial investment and specialized maintenance are challenges. Job displacement is a concern, yet experts see new job opportunities arising from automation in different areas.

Conclusion

The evolution of the warehousing and logistics sectors is profoundly shaped by automation. As e-commerce continues its rapid growth and as technologies like mobile robots and cloud-based warehouse management become more accessible, the transition to automated systems is not just an option—it’s a necessity.

Challenges, from integration difficulties to workforce adaptation, are present, but they’re overshadowed by the vast benefits: enhanced efficiency, cost savings, and the ability to meet rising customer demands promptly. As the warehouse automation market burgeons, businesses that lean into this transformation will undoubtedly be the frontrunners in the industry’s future.

References

https://roboticsandautomationnews.com/2023/01/14/4-real-world-examples-of-warehouse-automation-to-spark-your-inspiration/59066/

https://6river.com/warehouse-automation-statistics/#

https://www.alliedmarketresearch.com/warehouse-automation-market-A17070

https://synder.com/blog/how-does-warehouse-automation-reduce-costs/

https://www.sdcexec.com/warehousing/automation/news/22877126/proglove-warehousing-and-logistics-industry-torn-about-automation-study

https://www.precedenceresearch.com/warehouse-automation-market

https://www.prologis.com/news-research/global-insights/future-proofing-global-supply-chain-how-ai-automation-and-other