Exploring Raymond Corporation’s latest innovation, the Raymond Integrated Tether System, promises to redefine forklift safety in modern warehouses. This piece delves into its features, benefits, and potential impact on the material handling industry.

As industries evolve, they constantly seek ways to enhance operational efficiency and safety. One such sector that exemplifies this commitment is material handling. The Raymond Corporation, a frontrunner in material handling solutions, has recently introduced its state-of-the-art Integrated Tether System, further solidifying its reputation as a workplace safety champion.

The Modern Warehouse:

Challenges and Needs Modern warehouse operations have undergone significant changes. With the global expansion of e-commerce and just-in-time delivery systems, the volume of goods passing through warehouses has skyrocketed.

As warehouses grow in size and complexity, the number of operators working simultaneously in these facilities also increases. The upsurge presents its own set of challenges, the foremost being ensuring the safety of all operators.

Traditional safety systems have proven less effective against the backdrop of evolving warehouse designs and the increasing speed of operations. Hence, the material handling industry is at an inflection point where technology must be harnessed to provide efficient safety solutions.

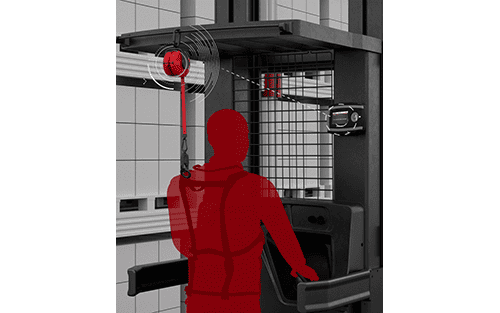

Decoding the Integrated Tether System The Integrated Tether System is Raymond Corporation’s answer to modern safety challenges. At its core, the system prioritizes prevention over cure. It is designed meticulously and utilizes an intelligent tether with advanced sensors.

These sensors continuously monitor whether the operator is securely tethered to the forklift. No matter how minor, any discrepancy triggers an immediate response, immobilizing the equipment. This instantaneous reaction is crucial in preventing potential mishaps from an operator not being securely fastened.

The words of Shannon Curtis, the Product Manager at Raymond Corporation, shed light on the industry’s challenges and the corporation’s proactive approach. Over the last several years, facility owners and managers have faced the problem of increasing warehouse operator count.

Alongside, there’s been a pressing need to reinforce and continually monitor best practices. This dual challenge has created a demand for technologically robust solutions that address these pressing concerns,” she remarked.

A Dual-Purpose System

Safety and Reporting Raymond Corporation’s innovation is not limited to just safety. The Integrated Tether System also stands out for its robust reporting capabilities. This feature caters to the administrative and management side of warehouse operations. The system offers a wealth of data by creating detailed logs of operator connection histories and system engagements. Managers can harness this information for:

- Training Modules: With insights from the system, training programs can be tailor-made to address specific areas where operators might require additional instruction.

- Operational Streamlining: By understanding operator patterns and system usage, workflows can be optimized, enhancing warehouse efficiency.

- Ensuring Compliance: The data confirms that safety protocols are not just theoretical guidelines but are practically adhered to, creating a culture where safety is ingrained in every operation.

Seamless Compatibility and Integration What adds another feather to the cap of the Integrated Tether System is its wide compatibility range. It is meticulously designed to integrate effortlessly with various Raymond models, including the iWAREHOUSE Telematics and a series of very narrow aisle models. The system’s adaptability ensures that facilities equipped with Raymond forklifts can easily upgrade to this advanced safety mechanism.

Final Thoughts

The introduction of the Integrated Tether System by Raymond Corporation is more than just a product launch. It symbolizes the industry’s shift towards a future where technology and safety coalesce seamlessly. Raymond has set a commendable standard by amalgamating cutting-edge technology with safety protocols. As warehouses evolve, such innovations will be the cornerstone, ensuring that efficiency and safety walk hand in hand.

Sources

https://www.raymondcorp.com/

https://www.raymondcorp.com/news/2023/integrated-tether

https://ohsonline.com/articles/2023/06/26/safety-measures-in-warehouses-and-fulfillment-centers.aspx?m=1

https://www.associated-solutions.com/technology/iwarehouse