In this comprehensive guide, we will explore the different types of forklifts, their classifications, and their applications. Whether you’re working in a warehouse, construction site, or any other industrial setting, understanding the various forklift types and classes will help you choose the right equipment for your specific needs.

Key Takeaways

- There are various types of forklifts, each with different features and applications.

- Forklifts are classified into different classes based on their power source and function.

- Choosing the right forklift for your operations is crucial for efficiency and safety.

- Consider factors such as load capacity, lift height requirements, and work environment when selecting a forklift.

- Understanding forklift classifications can help you narrow down your options and make an informed decision.

Introduction

When it comes to forklifts, making the right choice is crucial for maximizing efficiency, productivity, and safety in your work environment. Understanding the different types and classes of forklifts will help you determine which one is best suited for your specific needs.

When choosing a forklift, there are several key factors to consider. The type of work environment plays a significant role in determining the appropriate forklift type. Whether you are working in a warehouse, construction site, or other industrial settings, each environment has its unique demands and requires a forklift that can navigate and operate efficiently within those conditions.

Another essential factor to consider is the load capacity requirements. Forklifts come in various weight capacities, and selecting the right one ensures that you can safely lift and transport the desired loads without exceeding the forklift’s capabilities.

Specific applications are also crucial when choosing a forklift. Different forklift types are designed for diverse tasks, such as lifting and stacking pallets, reaching high heights, or maneuvering in rough terrain. By understanding your specific application requirements, you can select a forklift that is optimized for the tasks at hand.

Overview of Common Forklift Types

In this section, we will provide an overview of the most common types of forklifts used in various industries. Understanding the different forklift types will help you determine which one is best suited for your specific needs. Let’s explore each type in detail:

Warehouse Forklifts

Warehouse forklifts are designed for indoor use and are commonly used in warehouses and distribution centers. They are ideal for lifting and moving heavy loads within confined spaces. These forklifts come in different sizes and load capacities, allowing for efficient maneuvering and stacking of pallets and materials.

Examples and Applications:

Standard Electric Counterbalance Forklifts: Often seen in smaller to medium-sized warehouses, these forklifts are adept at general pallet moving. For instance, a beverage distribution center might use them for loading and unloading pallets of drinks from delivery trucks and moving them to storage areas.

Reach Trucks: In warehouses with high shelving, reach trucks are invaluable. They have an extended lift height, ideal for stacking and retrieving pallets from high shelves. An example would be a book distribution center, where reach trucks efficiently handle books stored at various levels.

Side Loaders: These are particularly useful in handling long or awkwardly shaped items like timber or metal sheets. In a hardware supply warehouse, side loaders deftly move these long items through narrow aisles without obstructing the path.

Walkie Stackers: For warehouses that handle lighter loads or have limited space, walkie stackers offer a compact and maneuverable solution. They are perfect for small-scale operations like a local retail warehouse, handling pallets in tight spaces.

Advantages of Warehouse Forklifts:

Space Optimization: With their ability to navigate tight spaces, warehouse forklifts enable more efficient use of warehouse space, a critical factor in busy storage facilities.

Task-Specific Design: Various models cater to specific tasks, enhancing operational efficiency. For example, reach trucks are designed for high shelving, while side loaders are best for long loads.

Enhanced Safety Features: Considering the indoor operation, these forklifts often include safety features like better visibility and precise controls, crucial in the hustle of warehouse activities.

Side Loaders and Counterbalance Forklifts

Side Loaders: Side loaders are uniquely designed for handling long or bulky items, making them a go-to choice in environments where space efficiency is key. Their ability to lift loads from the side allows them to operate in narrow aisles and tight spaces, which is particularly advantageous in warehouses storing lengthy materials such as lumber, pipes, or steel sheets.

Examples and Applications:

- Lumber Yards: In a lumber yard, side loaders efficiently transport long planks of wood, navigating through narrow spaces between stacks with ease.

- Metal Warehouses: For warehouses storing metal sheets or long bars, side loaders can move these materials without the need for extensive clearance space, enhancing operational efficiency.

Advantages:

- Space Efficiency: The side-loading feature allows for effective maneuvering in narrow aisles, maximizing the use of storage space.

- Handling Long Loads: They are specifically designed to handle long loads safely and efficiently, reducing the risk of damage to the materials and the surroundings.

Counterbalance Forklifts: Counterbalance forklifts, recognized for their versatility, are a fundamental element in various industries. These forklifts have a weight distribution system that counterbalances the load, eliminating the need for outriggers. This makes them suitable for a wide range of lifting tasks, especially where the load size and shape vary.

Examples and Applications:

- General Warehousing: Ideal for general warehousing needs, these forklifts handle palletized goods, from unloading trucks to stocking shelves.

- Manufacturing Facilities: In manufacturing settings, counterbalance forklifts are versatile enough to move raw materials to production lines and finished products to storage areas.

Advantages:

- Versatility: Capable of handling a diverse range of load types and sizes, making them a versatile asset in various industrial settings.

- No Additional Stabilization Required: Their design negates the need for extra stabilization, allowing for quicker and more efficient load handling.

In essence, side loaders and counterbalance forklifts are indispensable in settings where the nature of goods and spatial constraints require specialized handling. Each type brings unique benefits – side loaders with their ability to navigate narrow spaces with long loads, and counterbalance forklifts with their versatility and efficient load-balancing capabilities.

Telehandlers and Heavy-Duty Forklifts

Telehandlers: These versatile machines stand out in their category due to their telescopic boom, which extends both vertically and horizontally. This unique feature gives telehandlers an edge in applications where both reach and height are crucial.

Examples and Applications:

- Construction Sites: Telehandlers are invaluable on construction sites, where they can be used to move heavy materials like bricks or steel beams to higher floors, or across obstacles.

- Agricultural Settings: In agriculture, they are instrumental in tasks like stacking bales of hay or moving large bags of feed, demonstrating their versatility beyond typical industrial uses.

Advantages:

- Extended Reach: The telescopic boom enables operators to reach heights and distances that are inaccessible to standard forklifts.

- Versatility: With the ability to attach different kinds of tools, such as buckets or pallet forks, telehandlers can perform a variety of tasks, making them a multi-purpose asset.

Heavy-Duty Forklifts: Built to handle the most demanding tasks, heavy-duty forklifts are the workhorses of industrial settings. Their high load capacities allow them to move extremely heavy goods with ease, a feature essential in many heavy industrial environments.

Examples and Applications:

- Shipping Ports: In these settings, heavy-duty forklifts are used for loading and unloading large shipping containers, demonstrating their capacity to handle substantial weights.

- Steel Mills: These forklifts are also common in steel mills, where they transport large coils or plates of steel, showcasing their ability to manage heavy and bulky loads.

Advantages:

- High Load Capacity: Capable of handling significantly heavier loads than standard forklifts, they are indispensable in industries where large and heavy materials are the norms.

- Durability: Built to withstand harsh environments and heavy usage, heavy-duty forklifts offer reliability in challenging industrial settings.

Telehandlers and heavy-duty forklifts are essential in sectors where standard forklifts are inadequate. Their specialized designs and capabilities make them ideal for handling tasks that involve high reach, heavy loads, and challenging terrains.

Rough Terrain Forklifts

Rough terrain forklifts are engineered to excel in environments where traditional forklifts might falter. Their hallmark feature is the ability to operate effectively on uneven and challenging terrains, making them indispensable in various outdoor applications.

Key Characteristics and Capabilities:

- Large, Rugged Tires: These forklifts are equipped with large tires that have deep treads, providing the necessary traction to navigate through mud, gravel, and other rough surfaces.

- High Ground Clearance: They also boast a higher ground clearance than standard forklifts, allowing them to overcome obstacles and uneven terrain without sustaining damage.

Examples and Applications:

- Construction Sites: On construction sites, rough terrain forklifts efficiently transport building materials over uneven grounds, from one part of the site to another, aiding in the swift progression of construction projects.

- Lumber Yards: In lumber yards, they maneuver through rough paths while carrying heavy loads of timber, showcasing their strength and stability in rugged conditions.

Advantages:

- Adaptability to Rough Conditions: These forklifts are specifically designed to operate in conditions where other forklifts would be ineffective, ensuring continuity of work in challenging environments.

- Versatility in Load Handling: Despite the tough exterior, rough terrain forklifts are versatile in handling various types of loads, from palletized goods to bulky construction materials.

- Durability and Reliability: Built to withstand harsh conditions, they offer a level of durability and reliability that is essential for rigorous outdoor tasks.

Rough terrain forklifts are a critical asset in industries and settings where the ground conditions are less than ideal. Their design and capabilities ensure that operations can continue smoothly, even in the most challenging outdoor environments.

By choosing a rough terrain forklift, businesses can ensure efficient, safe, and reliable handling of materials, regardless of the surface conditions.

Pallet Jacks and Walkie Stackers

Pallet jacks and walkie stackers are designed for efficiency and ease of use in spaces where larger forklifts might be impractical. Their compact and maneuverable nature makes them ideal for a variety of applications in warehouses and retail environments.

Pallet Jacks: Pallet jacks, also known as pallet trucks, are the simplest form of forklift and are highly valued for their straightforward operation. These manually operated devices are perfect for moving pallets over short distances.

Examples and Applications:

- Retail Stores: In retail settings, pallet jacks are used to transport deliveries from storage areas to shelves, offering a quick and easy way to move stock.

- Small Warehouses: For smaller warehouses with limited space, pallet jacks provide an efficient solution for moving goods without the need for more complex machinery.

Advantages:

- Ease of Use: Their manual operation requires minimal training, making them accessible to a wide range of employees.

- Cost-Effectiveness: Pallet jacks are an affordable option for businesses that need basic pallet moving capabilities without the investment in larger, more expensive equipment.

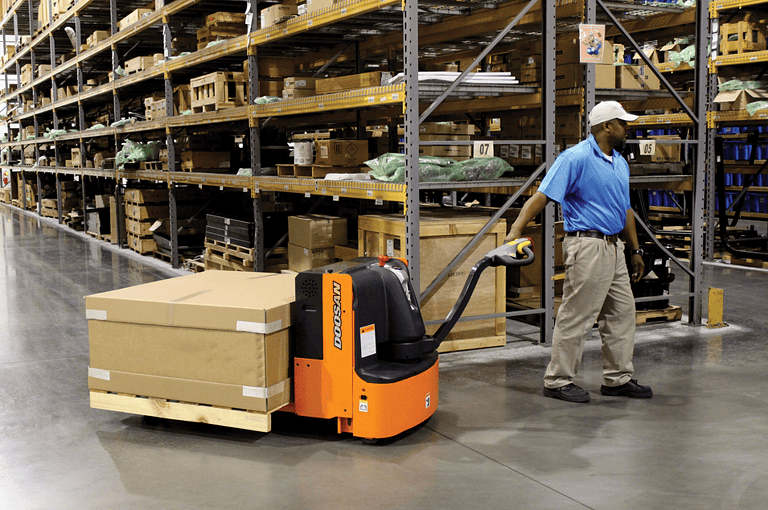

Walkie Stackers: Walkie stackers are a step up from pallet jacks, offering electric power for lifting and moving pallets. They are particularly useful in environments where products need to be stacked at height.

Examples and Applications:

- Warehouse Operations: In warehouses, walkie stackers are used for stacking pallets at higher levels, especially useful in areas where space is at a premium and goods need to be stored vertically.

- Loading and Unloading Tasks: They are also efficient for loading and unloading tasks in small to medium-sized business operations, where a full-sized forklift might not be necessary.

Advantages:

- Increased Lifting Capacity: Unlike manual pallet jacks, walkie stackers can lift heavier loads to a greater height, increasing storage efficiency.

- Maneuverability: Their compact size and powered operation make them ideal for navigating narrow aisles and tight spaces.

Pallet jacks and walkie stackers are essential tools in many warehouse and retail settings. They offer a combination of simplicity, efficiency, and cost-effectiveness that is unmatched by larger, more complex forklifts. Their adaptability makes them suitable for a wide range of material handling tasks, from simple ground-level pallet transport to more complex stacking and storage operations.

Order Pickers and Reach Fork Trucks

Order pickers and reach fork trucks are specialized forklifts designed to optimize the retrieval and placement of goods in warehouse and distribution center settings, particularly where vertical storage is extensively utilized.

Order Pickers: These forklifts are tailored for manual picking processes, allowing the operator to be lifted along with the platform to the desired height. This design is especially advantageous in situations where individual items, rather than entire pallets, need to be picked from shelving.

Examples and Applications:

- E-Commerce Fulfillment Centers: In these centers, where a vast variety of individual items must be picked quickly and efficiently, order pickers are essential for accessing various levels of shelving.

- Parts Warehouses: In settings where small parts are stored at different heights, such as automotive parts warehouses, order pickers facilitate the easy retrieval of these items.

Advantages:

- Precision in Picking: They allow for precise and easy selection of specific items, improving accuracy in fulfilling orders.

- Enhanced Safety for Operators: By moving the operator to the level of the goods, order pickers reduce the need for stretching or reaching, thereby enhancing safety.

Reach Fork Trucks: These trucks are distinguished by their extended reach capability. The forks can extend beyond the truck body, allowing them to reach deep into shelving units, making them ideal for handling palletized goods in narrow aisles.

Examples and Applications:

- High-Density Storage Facilities: In facilities where space optimization is crucial, reach fork trucks efficiently handle pallets in narrow aisles, maximizing storage space.

- Large Distribution Centers: For centers that store and move large volumes of palletized goods, reach fork trucks streamline the process of stacking and retrieving pallets from high shelves.

Advantages:

- Space Efficiency: Their ability to operate in narrow aisles allows for more efficient use of warehouse space.

- Increased Storage Capacity: By enabling high stacking of pallets, they contribute significantly to increasing the overall storage capacity of a facility.

Order pickers and reach fork trucks are integral to modern warehousing operations, particularly in settings where space optimization and efficient retrieval of goods are paramount. Their specialized designs cater to specific needs within the warehouse, enhancing both productivity and safety in material handling.

Forklift Classifications Explained

In this section, we will explain the different classifications of forklifts as defined by industry standards. Understanding the various forklift classifications can help you make an informed decision when choosing the right forklift for your specific needs. Let’s delve into each class:

Class I – Electric Motor Rider Forklifts

The Class I forklifts are electric motor rider forklifts that are powered by rechargeable batteries. These forklifts are designed for indoor use and are commonly used in warehouses, distribution centers, and manufacturing facilities.

In addition to their electric power source, they are known for their maneuverability, quiet operation, and zero-emission operation. The electric motor rider forklifts are ideal for loading and unloading pallets, stacking materials, and transporting heavy loads over short distances.

Class II – Electric Motor Narrow Aisle Trucks

The Class II forklifts, also known as electric motor narrow aisle trucks, are specifically designed for use in narrow aisle spaces, such as high-density racking systems commonly found in warehouses and distribution centers.

These forklifts feature a compact design and are equipped with specialized features, such as a reach mechanism or a guided rail system, allowing them to navigate tight spaces efficiently. The electric motor narrow aisle trucks are ideal for order picking, stock replenishment, and optimizing storage density.

Class III – Electric Motor Hand Trucks

The Class III forklifts, often referred to as electric motor hand trucks, are designed for manual operation with an electric power assist. These forklifts are commonly used for material handling tasks that involve lifting and transporting relatively lighter loads. Electric motor hand trucks are versatile and can be used in various applications, including retail stores, supermarkets, and small warehouses. Their compact size and maneuverability make them ideal for navigating narrow aisles and confined spaces.

Class IV & V – Internal Combustion Engine Forklifts

The Class IV and V forklifts are categorized as internal combustion engine forklifts and are primarily used for outdoor applications or in areas where ventilation is adequate. Class IV forklifts are equipped with cushion tires and are designed for smooth surfaces, such as concrete or asphalt.

These forklifts are commonly used in indoor/outdoor warehouses, shipping yards, and manufacturing sites. Class V forklifts, on the other hand, are equipped with pneumatic tires, which make them suitable for rough or uneven terrain, such as construction sites or lumber yards. The internal combustion engine forklifts offer high performance, durability, and the ability to handle heavy loads.

Class VI – Electric and Internal Combustion Engine Tractors

The Class VI forklifts are electric and internal combustion engine tractors used for towing and hauling heavy loads, both indoors and outdoors. These forklifts are commonly used in settings where material transport over long distances is required, such as airports, distribution centers, and manufacturing facilities. Electric and internal combustion engine tractors offer versatility, power, and efficiency in a variety of applications.

Class VII – Rough Terrain Forklift Trucks

The Class VII forklifts, also known as rough terrain forklift trucks, are designed for outdoor use on rough and uneven terrain. These forklifts are commonly used in construction sites, lumber yards, and agricultural settings.

Rough terrain forklift trucks are equipped with large, rugged tires and powerful engines to handle challenging conditions. They are capable of lifting and transporting heavy loads in off-road environments, making them essential for outdoor material handling tasks.

Forklift Sizes and Elements

Understanding the dimensions and features of forklifts is crucial for selecting the right equipment that can efficiently handle your workload and meet your operational requirements.

The size of a forklift is determined by several factors, including:

- Load Capacity: This refers to the maximum weight a forklift can safely lift and carry. Forklifts come in different load capacities, ranging from small electric models with a capacity of a few thousand pounds to large diesel-powered forklifts capable of lifting several tons.

- Lift Height: The lift height of a forklift indicates how high it can raise its forks. Forklifts equipped with masts can achieve varying lift heights, allowing for efficient stacking and retrieval of goods in warehouses or storage facilities.

- Mast Types: Forklifts can feature different types of masts, such as standard masts, triple-stage masts, or telescopic masts. Each type offers unique benefits in terms of lift height, stability, and maneuverability.

- Tires: Forklifts can be equipped with different types of tires, including pneumatic tires, cushion tires, or solid rubber tires. The type of tires affects the forklift’s performance on different surfaces, such as concrete, gravel, or uneven terrain.

- Other Elements: Forklifts may have additional elements such as attachments for specific tasks, ergonomic features for operator comfort, and safety features like lights, alarms, and cameras.

By considering these elements, you can determine the ideal forklift size that will optimize your workflow, ensure safety, and provide efficient material handling capabilities.

| Forklift Size | Load Capacity (in pounds) | Lift Height (in feet) | Tire Type |

|---|---|---|---|

| Small Electric | 2,000 – 5,000 | 10 – 20 | Cushion |

| Large Diesel | 15,000 – 40,000+ | 20 – 30+ | Pneumatic |

| Narrow Aisle | 3,000 – 5,000 | 20 – 40 | Solid Rubber |

The table above provides a sample comparison of different forklift sizes, showcasing their load capacity, lift height, and tire type. Remember to consult the manufacturer’s specifications for specific forklift models to determine the most appropriate size and features for your requirements.

How To Choose The Right Forklift

Choosing the right forklift for your specific needs is crucial to ensure efficient and safe operations in your workplace. In this section, we will provide a step-by-step guide to help you navigate the process of selecting the ideal forklift.

1. Determine Your Load Capacity Requirements

Start by assessing the maximum weight you need your forklift to lift and carry. Consider both the average and peak loads to ensure that the forklift you choose can handle your workload without exceeding its capacity.

2. Evaluate Your Lift Height Requirements

Take into account the maximum height your forklift will need to reach to perform the required tasks. Consider factors such as rack heights in your warehouse or the height of trucks or containers your forklift needs to load or unload.

3. Consider Your Work Environment

Assess the conditions and layout of your work environment. If you primarily operate indoors in narrow aisles, you may need a narrow aisle forklift or a reach truck. Alternatively, if you work outdoors on rough terrain, a rough terrain forklift may be more suitable.

4. Think About Fuel Type

Determine the most appropriate fuel type for your operations. Electric forklifts are clean, quiet, and suitable for indoor use, while internal combustion engine forklifts are better suited for outdoor applications where refueling infrastructure is readily available.

5. Set Your Budget

Define your budget range for purchasing or leasing a forklift. Consider not only the upfront cost but also long-term maintenance and operational expenses. Find a balance between budget constraints and acquiring a reliable and durable forklift that meets your requirements.

6. Research Trusted Brands and Models

Take the time to research reputable forklift brands and models that have a proven track record of reliability and performance. Look for reviews, seek recommendations, and consult with industry experts to help you narrow down your options.

7. Test and Compare

If possible, arrange to test different forklift models before making a final decision. Compare their ergonomics, maneuverability, operator comfort, and other features that are important for your specific operations. This hands-on evaluation can provide valuable insights to inform your choice.

8. Consult with Experts

If you have any doubts or need additional guidance, consult with experienced forklift professionals. They can offer invaluable advice tailored to your unique requirements and help ensure that you select the best forklift for your specific needs.

By following these step-by-step guidelines and carefully considering load capacity, lift height, work environment, fuel type, budget, and expert advice, you’ll be equipped to choose the right forklift that will enhance productivity and safety in your operations.

Conclusion

In conclusion, selecting the right forklift is crucial for ensuring smooth and efficient operations in your warehouse or industrial setting. By understanding the different types and classes of forklifts, you can make an informed decision based on your specific needs and requirements.

Throughout this guide, we have explored the various types of forklifts, including warehouse forklifts, side loaders, telehandlers, and more. We have also discussed the classifications of forklifts, ranging from electric motor rider forklifts to rough terrain forklift trucks.

Remember, when choosing a forklift, consider factors such as load capacity, lift height, work environment, and budget. Taking these aspects into account will help you select the right forklift that can handle your workload effectively and optimize your operations.

For more information and detailed specifications, refer to reputable forklift manufacturers such as Toyota, Caterpillar, and Hyster. They offer a wide range of forklifts to suit various applications and provide valuable resources to help you make the best choice for your business.

Frequently Asked Questions

How are forklifts classified?

Forklifts are classified into different classes based on their power sources and specific features. The classifications are: Class I – Electric Motor Rider Forklifts, Class II – Electric Motor Narrow Aisle Trucks, Class III – Electric Motor Hand Trucks, Class IV & V – Internal Combustion Engine Forklifts, Class VI – Electric and Internal Combustion Engine Tractors, and Class VII – Rough Terrain Forklift Trucks.

How can I choose the right forklift for my needs?

To choose the right forklift, you should consider factors such as load capacity requirements, lift height, work environment (indoor or outdoor), specific applications, and budget. By analyzing these factors, you can select a forklift that meets your operational needs and ensures optimal efficiency and safety.

What are the different types of forklifts?

A forklift is a type of industrial truck commonly used to lift and move materials within a warehouse or in outdoor settings. There are several types of forklifts including counterbalance forklifts, narrow aisle forklifts, rough terrain forklifts, and reach forklifts.

What are the classes of forklifts and their applications?

The class I forklift is electric and primarily used indoors in warehouses to handle pallets. Class II forklifts are electric and best suited for narrow aisle applications. Class III forklifts are electric pallet jacks, commonly used for moving materials within a warehouse. Class IV forklifts are powered by internal combustion engines and are ideal for rough terrain applications. Class V forklifts are typically used in warehouses and are powered by internal combustion engines.

What are the main differences between the various forklift types?

The main difference between the different types of forklifts lies in their applications. For instance, counterbalance forklifts are designed for handling pallets in warehouses, while rough terrain forklifts are best suited for outdoor use and can handle heavy loads on uneven surfaces.